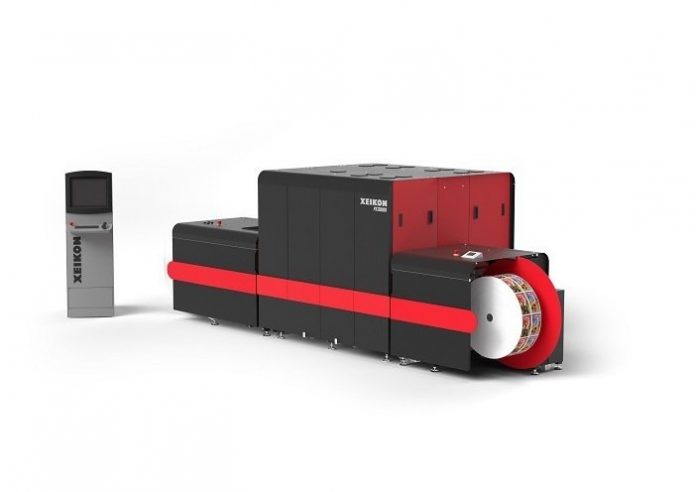

Digital printing technology provider, Xeikon has announced the addition of a high-end label press to its Panther portfolio to meet a need in the market and extend the company’s comprehensive offering, broadening the application reach. Providing high productivity levels, the Xeikon PX30000 is equipped with eight printing stations, two of which are used to achieve high opaque white layers at maximum speed. This UV inkjet label press is driven by Xeikon’s unsurpassed X-800 digital front end with exceptional capabilities, all geared to maximize digital print manufacturing.

According to the company, the Xeikon PX30000 UV inkjet press offers a cost-effective and fast time-to-market solution for short to medium run flexo jobs. It offers the label printer with maximum opportunities to produce the widest range of digitally printed labels with a glossy tactile look, optimum durability, and high levels of resistance against scuffing and scratching.

The press is designed to appeal in particular to label printers working in the high-end markets of health and beauty, chemicals, and premium beers. Label printers looking for faster turnaround times, reduced production costs, and lower complexity will be able to explore new business possibilities offered by digital printing, it said. Xeikon’s PX30000 is now available for demonstration at Xeikon’s Global Innovation Center and is commercially available in Europe and North America.

Filip Weymans, vice president of Marketing at Xeikon, states, “The addition of this high-end, digital production label press is an important step in the Xeikon strategy. Adding the Xeikon PX30000 to our portfolio enhances the Xeikon offering that already was the most comprehensive in the market. Label printing companies can now opt for a dry toner press or an inkjet press, for an entry-level solution or a fully geared high-end production press, from a 5 color engine up to a 7 color engine. We are convinced that the appropriate and ideal choice a printing customer makes depends on their business strategy and their choice of end-use applications.”

Weymans continues, “We are recognized as a ‘go-to’ trusted advisor and solutions provider. Throughout the years, Xeikon has developed a suite of the most relevant services available, supporting its customers in developing and selling new applications, helping them with the integration of digital printing within their existing environments, and also assisting them in automating their complete label production.”

“Apart from integration capabilities, the X-800 workflow enables further automation for complete label production. Making use of its intelligent imposition algorithms to position the labels on the web can help reduce costs by optimizing production times. There are no challenges too great for this powerful workflow – even the most demanding variable data jobs or labels where the track and trace functionality is required – Xeikon’s X-800 workflow is unsurpassed.”

“Xeikon has the long-standing expertise and deeper understanding to help label printers with all aspects of running a successful digital label print business, from choice of equipment to workflow integration and expert color management services. Xeikon helps the label printer transform to a digital manufacturer.”

The company said Xeikon PX30000 digital press is a highly versatile solution offering a range of capabilities and features. As for all Xeikon digital printing technology, Overall Equipment Effectiveness (OEE) can be optimized using the available Xeikon Premium Services.

The Xeikon PX30000 UV inkjet press is a proven press platform driven by Xeikon’s X-800 workflow, which can be easily integrated into any existing workflow environment. For flexibility and a wider range of applications, the press has extended color gamut capability, it comes with a choice of 2 configurations – 6 or 7 color – and full-color management controls. With a maximum speed of 70m in a min (229ft in a min) and opaque white, the press is designed for maximum efficiency and industry-leading productivity. This roll-to-roll, full rotary press prints on substrate widths up to 340mm (13,4″).

Weymans adds, “The addition of the Xeikon PX30000 high-end label press to our portfolio immediately gives Xeikon a broader reach. We are committed to our vision of a digital future for Labels and Packaging. We are the only company dedicated to a true consultative approach, offering both dry toner and inkjet technologies and therefore the most comprehensive choice of digital solutions.”

An investment in the Xeikon PX30000 high-end label press with high productivity and extended color gamut will ensure an opportunity for label printers working with high-end products to provide brand owners with unique, creative, and durable, high-quality labels. Importantly, working with Xeikon means ease of mind, knowing not only that they can provide the widest range of digital equipment, but that they will also advise on the best choice of product for specific business needs, it said.

Weymans concludes, “We have continued to build and structure our comprehensive portfolio so that our customers can find everything they need from Xeikon. We believe it’s not just about finding the right digital equipment; it’s about working with a trusted partner who can offer the appropriate digital solution for any business model. We will continue to be on hand at all times to give confidence and continued support to our customers on their digital journey.”