This year’s Labelexpo, held in Brussels, Belgium, was one of the most interesting revelations so far this year, reports Nessan Cleary in Part 2 of our coverage. The show continues to grow, partly because it’s evolving into a general packaging show, but largely because labelling is still an active market sector with much continuing innovation. It was busy from the moment the doors opened, with all the exhibitors reporting lively business

This year’s Labelexpo, held in Brussels, Belgium, was one of the most interesting revelations so far this year, reports Nessan Cleary in Part 2 of our coverage. The show continues to grow, partly because it’s evolving into a general packaging show, but largely because labelling is still an active market sector with much continuing innovation. It was busy from the moment the doors opened, with all the exhibitors reporting lively business

and plenty of deals having subsequently been announced.

By far the most interesting aspect of Labelexpo Brussels was the general acceptance of digital technology. Labelling, and packaging as a whole, has been late to the digital party, mainly because it’s a business of long runs. But there’s a growing acceptance that if customers require runs of 10,000 or even 100,000 linear metres, then they will probably also need shorter runs of 1,000 metres or so at some point. The result is that most of the main manufacturers of narrow web flexo presses have now introduced hybrid presses with full color digital imaging.

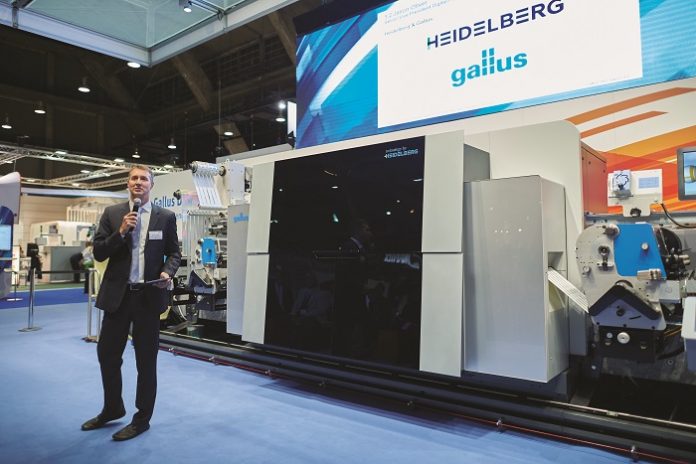

Gallus

Thus Gallus demonstrated its hybrid digital press, the DCS340,the first new product to be announced since Heidelberg formally took over the company. Klaus Bachstein, CEO of Gallus, was at pains to point out that “Gallus is still Gallus” but its development clearly owes a lot to Heidelberg’s overall strategy. For starters, it’s driven by a label version of Heidelberg’s Prinect workflow.

But perhaps the most important aspect is the digital imaging, which uses Fujifilm Samba printheads with a Heidelberg-supplied UV ink. Jason Oliver, Heidelberg’s senior vice president for digital solutions, also confirmed that Heidelberg is developing a B1 digital press, also with the Samba heads though with water-based inks for the commercial print market. This will be shown at drupa and will compete directly with the Landa presses.

Thanks to the Samba heads, the DCS340 boasts of a relatively high resolution of 1,200 x 1,200 dpi, with a tiny two picolitre drop size. It can run at 45 metres a minute, which is a fairly standard speed for inkjet label presses. It’s an8-colormachine,having CMYK plus orange, green and violet for an extended color gamut, as well as white. Being a hybrid machine with flexo units, it has in-line finishing to allow for varnishing and diecutting. The plan is to use Heidelberg’s Multicolor fixed 7-color extended gamut set of inks.

Mark Andy

Mark Andy also showed off its new hybrid press, but was remarkably light on details. Kevin Wilken, CEO of Mark Andy, pointed out that most hybrids were developed by several companies working in partnership, claiming that Mark Andy had developed its press entirely in-house. However, he refused to name the major partner that had supplied the printheads, making it difficult to properly assess the long term reliability of this press. That said, it appears to be reasonably quick, running at roughly 75 metres a minute and delivering 600 x 600 dpi.

Domino

Domino showed off yet another variant of its N610i inkjet technology. Previously this has been shown as a complete press or as just the head units but Domino has now developed a complete digital imaging module that can be combined with flexo units to create a hybrid press. Philip Easton, Domino’s UK managing director, says, “It’s completely modular so you can add flexo stations with embossing, laminating or whatever.” It’s a 7-color device capable ofrunning up to 75 metres a minute with 600 dpiresolution.

Durst

Photo PSA

The market for digital label presses seems to be consolidating – there were still plenty of machines on show but some players are clearly better established than others and there’s less room for unknown companies to try their luck. Durst showed offitsTau330 labelpress but also launched a much cheaper version,theTau330E, in an attempt to appeal to a broader range of users. It’s available in 200 mm and 330 mm widths, withCMYK inks plus white as an option. It can produce up to 48 metres a minute, with a choice of 720 x 360 dpi or 720 x 1,260 dpiresolution. It also uses new highly pigmented inks that have been developed together withSunjet, which claim to reduce ink lay down by 20 to 30 % to keep the cost down. It’s also possible to add a digital laser for in-line cutting. Durst has also developed a browser-based workflow system, Tau Prepare, so that files can be uploaded from anywhere and the machine monitored remotely.

Dantex

The British company Dantex, mainly known for distributing pressroom consumables, showed off a brand new inkjetlabel press, the PicoColour 2. This has been developed by JF Machines, which Dantex took over earlier this year. The press itself is 210 mm wide and runs at up to 35 metres a minute. It uses Xaar 1002 printheads and offers CMYK plus white inks. There’s an optional corona unit and it can be used for paper as well as film-based media.

MPS

MPS has taken up the challenge from Domino, adding flexo units from its EF Neo press to the N610i to create a new hybrid, the EF Symjet. However, it does feel as if MPS has some work to integrate the two halves of the press together. Thus, the flexo units take media up to 430mmwide,whereas the digital unit can only handle media up to 330 mm wide. Hans Poorting a, product manager of MPS, says that the company is still working to integrate the software from the two halves. The inkjet inks will be supplied by Domino.

Konica Minolta

Nessan Cleary

Konica Minolta demonstrated its label press, the Bizhub Press C71cf, though it won’t be launched until 2016. This is an electrophotographic machine printing in CMYK using Konica Minolta’s Simitri HDE toner. It can run at up to 13.5 metres a minute with are solution of 1,200×1,200 dpi. It takes media up to 330 mm wide and can handle paper, both coated and uncoated, as well as synthetics and polypropylene.

It’s difficult to know what to make of this press – it’s much slower than most of the other digital devices, yet it was surrounded by a large crowd throughout the show. Miguel Pinto, managing director of Litho Formas, based in Portugal, which has beta tested this printer, says that the print quality is excellent and that this is the most important criteria in a short-run printer. Industrial Inkjet, which uses Konica Minolta printheads, launched another in its series of printhead modules. The MP500 is a complete single color printing system that can be added to existing presses or even to a finishing kit. It can printfull variable images in black, white, varnish or spot colors, as well as security inks such as IR black or UV-fluorescent. It boasts 600 dpiresolution and can run at up to 50 metres a minute. It’s 520 mm wide and thus suitable for small packaging systems as well as labels.

Xaar

Xaar also announced something similar, having developed a standalone print module based around the 1002 printheads. The heads have been stitched together to forma single print bar, available in widths from70mmto 560mm. The unit also includes ink channels, electronics to drive the heads and workflow so that it can be easily added to a conventional press. It was shown on FFEI’s Graphium, a 7-colorhybrid press, with the additional printbar module used to add white ink to create an 8- color printer.

HP

HP has improved its Indigo WS6800 roll-to-roll press. The new features include improved color matching, using the built-in spectrophotometer together with a new Labels and Packaging Print Server, which uses Esko technology to match spot colors. HP has also improved the fade resistance of its ElectroInk wet toner and added a Michelman DP680 primer to work with a wider range of media.

HP also showed off upgrade packages for both its 20000 and 30000 B2 Indigos. The 20000 gains a new slitter, reinsertion capabilities and a white ink for shrink sleeves. The 30000 can now work with metalized substrates as well as reinsertion capabilities. HP showed the 20000 working with an ABG Digicon 3000.

Indeed, most of the digital presses were shown in-line with some form of finishing with customers clearly looking for complete systems and not just for the imaging engine. The vast majority of the finishing solutions shown still take a conventional approach, which is hardly surprising since most finishing involves physically changing a label and that’s a lot harder than just throwing dots onto a blank media as a print engine does.

Xeikon

Nonetheless, Xeikon has risen to the challenge with the announcement of a new concept, called Fusion. This basically means adding modules to a standard Xeikon print engine for features such as in-line cutting, varnishing orfoiling, which can be slotted in as needed. But the key thing is that these are all digital rather than conventional modules. Wim Maes, CEO of Xeikon, believes that we’ll see more web to print in the label sector that will need a completely digital production line.

Xeikon also used the show for the commercial launchofitsCX3digital labelpress. This is a toner printer based on Xeikon’s Cheetah technology and can print at up to 30 metres a minute, across a 330 mm web, with 1,200 x 3,600 dpiresolution, delivering extremely good image quality.

In conclusion, the most interesting aspect of the show is the speed at which the label sector has adopted digital printing. It seems only a couple of shows ago that a handful of inkjet presses were bunched together in one hall vaguely hoping that the industry was ready for them. But that uncertainty is gone now, with digital machines liberally dotted around the show and a general acceptance of the need for shorter runs.

There are still some wrinkles to iron out. Many of the hybrid presses have not integrated the digital and flexo units particularly well, while some of the inkjet presses still struggle to get the right balance between cost and productivity though most can produce good enough image quality to hold their own against flexo presses. It seems inevitable that many of the digital vendors will start to look at wider web widths to tackle the packaging market.