Greater Noida based packaging machine manufacturer Clearpack and Rajasthan-based social incubator PilaniAtmaNirbhar Resource Center (PARC) has developed a low-cost ventilator ‘Respimatic 100.’ The quickly-built device is to aid in the overall needs for respiratory equipment and ventilators during the COVID-19 pandemic.

The Respimatic 100 is designed to fit in the capability gap between a hand-powered Ambu bag and a full-featured ventilator. According to Clearpack CEO, Govind Bhandari, “There are many situations where a complex ventilator is either unavailable or unaffordable, but a hand-powered Ambu bag falls way short of the need. The need for such a device will continue well beyond the current COVID-19 pandemic, especially in remote parts of India.”

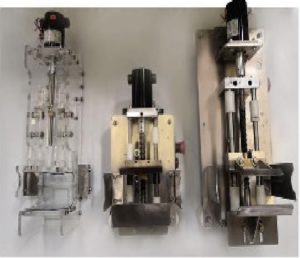

According to Clearpack, it took three days for three iterations of a new respirator design starting from scratch. In addition, working prototypes of three iterations have been undergoing stress tests continuously for the past number of days. Meanwhile, the company is readying all the necessary documentation required for formal certification from the concerned authorities. In parallel, Clearpack is working on its next version of the current device to add yet another critical ventilation mode.

The BITS alumni network

“In addition to the technical challenges, there were some unique challenges posed by the lockdown orders in force. The factories were closed; technical teams could not meet face-to-face, important components could not be sourced and other constraints. This is where the vast BITS alumni network came into play. All these issues were tackled and resolved on a war footing by connecting with alumni who were uniquely qualified for the task. We must also acknowledge the facilitation by the Greater Noida authorities, which was crucial,” Bhandari said.

The project was led by Bhandari, while his team included a geographically dispersed Clearpack workforce along with four doctors who advised on the clinical aspects, a ventilator design veteran who advised on the technical aspects and a medical electronics expert from Italy.

Bhandari also acknowledges that this respirator will need further refinement as it undergoes tests. He added, “No doubt that the certification process is arduous. No doubt, there will be unexpected challenges. However, that is what this team is geared up for. All in all, a great example of what large hearts, determination, and collaboration can do.”