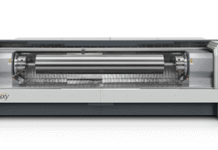

Tetra Pak‘s next generation high shear inline mixer offers customers unparalleled ingredient mixing performance and lower operating costs. Featuring a radical new design that produces finer, more consistent and more stable emulsions, the new R370-1000D reduces the need for downstream homogenization, delivers a better quality end product and cuts energy bills. Monica Gimre, executive vice president, processing systems at Tetra Pak, said, “We developed this revolutionary new design in direct response to customer needs. A complete break with the status quo, our new mixer streamlines production steps, reduces investment needs, lowers costs and sets a new benchmark for the industry.”

Crucial to this innovative new mixer is the unique restructuring and integration of a built-in de-aerating system, a flexible powder introduction system and a newly designed mixing head. This allows the new machine to handle the highest viscosities for a recirculation mixer at up to 2,000 cP and break the size of the droplets to 1 micron (0.001 mm), significantly smaller than the industry average of 7 microns.

The output of a much finer, more consistent and more stable emulsion reduces the need for downstream homogenisation, a highly energy-intensive step in food processing. This means that it is now possible to eliminate the homogenisation step altogether in the production of certain types of ice creams, cutting energy consumption by up to 50% in the overall process.

The new mixer can also handle ingredients with up to 65% dry matter, the highest concentration for infant formula production. This cuts down the need for evaporation, another expensive step in food processing, slashing costs by up to 90%. The mixing machine produces at a capacity of up to 30,000 liters per hour and can be applied in the production of liquid dairy and beverages, ice cream and prepared food, as well as for most premixing needs in food manufacturing. Tetra Pak holds a number of patents and pending patents for the Tetra Pak High Shear Mixer R370-1000D.